Top 10 Benefits of Chemical Blending for Industry Efficiency and Quality

In today’s fast-paced industrial landscape, efficiency and quality are paramount for organizations striving to maintain a competitive edge. One strategy that has gained significant traction is chemical blending, a process that not only enhances product performance but also streamlines operations. Dr. Emily Carter, a leading expert in chemical engineering, emphasizes the transformative power of this technique by stating, “Chemical blending is not just about mixing substances; it’s about creating superior products that meet diverse industry needs.”

The top benefits of chemical blending extend beyond mere cost savings. By optimizing formulations and ensuring consistency, businesses can achieve greater product quality and reliability. This approach allows companies to innovate rapidly while reducing waste and minimizing environmental impact. Furthermore, as industries evolve, the ability to blend chemicals effectively becomes essential for meeting regulatory requirements and customer expectations.

As we delve into the top 10 benefits of chemical blending for industry efficiency and quality, it becomes clear that this process is a cornerstone of modern manufacturing. By understanding and leveraging its advantages, companies can not only improve their bottom line but also contribute to a more sustainable future.

Overview of Chemical Blending and Its Role in Industry

Chemical blending plays a pivotal role in enhancing industry efficiency and improving product quality across various sectors. As the chemical sector is the largest industrial energy consumer, effective blending processes can significantly optimize energy use and minimize waste, aligning with global sustainability goals. This process involves meticulously combining different chemicals to create formulations that meet specific performance criteria. By leveraging advanced blending techniques, manufacturers can ensure consistent quality in their products while reducing the risk of errors or contamination.

Moreover, proper understanding of chemical blending is essential for safety in industrial settings. The chemical industry's operations come with inherent risks, such as the potential for uncontrolled reactions, highlighted by the violent reactions between reactive substances like nitric acid and organics. Therefore, training and adherence to industry best practices in chemical handling are crucial. As the global chemical production is projected to grow, investing in efficient blending processes will not only enhance productivity but also improve the overall safety and sustainability of chemical manufacturing. This synergy between efficiency and quality is vital as industries strive towards more environmentally friendly practices while meeting increasing consumer demands.

Enhancing Product Consistency Through Chemical Blending

Chemical blending plays a crucial role in enhancing product consistency across various industries. By integrating multiple raw materials into a homogenous mixture, manufacturers can significantly reduce variations in product quality. This uniformity is vital, especially in sectors such as pharmaceuticals, food production, and cosmetics, where precise formulations are critical to meeting regulatory standards and consumer expectations. Consistent products not only boost consumer trust but also facilitate smoother production processes, reducing waste and minimizing the need for costly rework.

Moreover, chemical blending enables manufacturers to optimize their formulations by adjusting the proportions of ingredients to achieve desired characteristics. This flexibility allows for fine-tuning products to better match specific performance criteria, thereby enhancing overall efficiency. For instance, in the coating industry, blending different resin types can lead to improved application properties and durability, ultimately resulting in a higher quality finish. The ability to produce consistent, high-quality products through effective chemical blending streamlines production operations and serves as a key competitive advantage in an increasingly demanding market.

Top 10 Benefits of Chemical Blending for Industry Efficiency and Quality

Improving Production Efficiency with Chemical Blending Techniques

Chemical blending plays a crucial role in enhancing production efficiency across various industries, particularly in the manufacturing of paints, coatings, and adhesives. According to a report by MarketsandMarkets, the global chemical blending market is expected to reach USD 10.5 billion by 2027, indicating a robust growth driven by companies seeking to optimize their operational processes. With efficient blending techniques, businesses can achieve a uniform product consistency, which reduces the time spent on quality control and minimizes waste. This, in turn, leads to significant savings in both material costs and production time.

Advanced blending technologies, such as vacuum blending and continuous mixing, enable manufacturers to produce higher-quality mixtures with precise formulations. For instance, a case study highlighted by ChemTech Services found that utilizing advanced blending systems reduced cycle times by up to 30%, while simultaneously improving product quality and reducing batch variability. As companies increasingly adopt these innovative blending techniques, they not only enhance their output efficiency but also position themselves competitively in the market, where reliable product quality is paramount for client retention and growth.

Cost Reduction Strategies Achieved via Chemical Blending

Chemical blending has emerged as a powerful strategy for industries seeking cost reduction while enhancing quality. By mixing various raw materials efficiently, businesses can optimize their production processes and minimize waste. This not only leads to lower material costs but also streamlines labor expenses associated with handling multiple ingredients separately. As a result, companies can allocate their resources more effectively, achieving significant savings over time.

Tips for successful chemical blending include investing in quality blending equipment, which ensures homogeneous mixtures and reduces the risk of defects. Additionally, conducting regular evaluations of the blending process can identify areas for improvement, allowing companies to adapt their strategies based on changing production needs. Lastly, maintaining strong relationships with suppliers can help secure better pricing on raw materials, further contributing to overall cost efficiencies.

Moreover, the use of advanced software for inventory management can complement chemical blending techniques, allowing businesses to precisely track ingredient usage and forecast future needs. Incorporating these strategies will not only reduce costs but also improve the consistency and quality of the final products, reinforcing a competitive edge in the market.

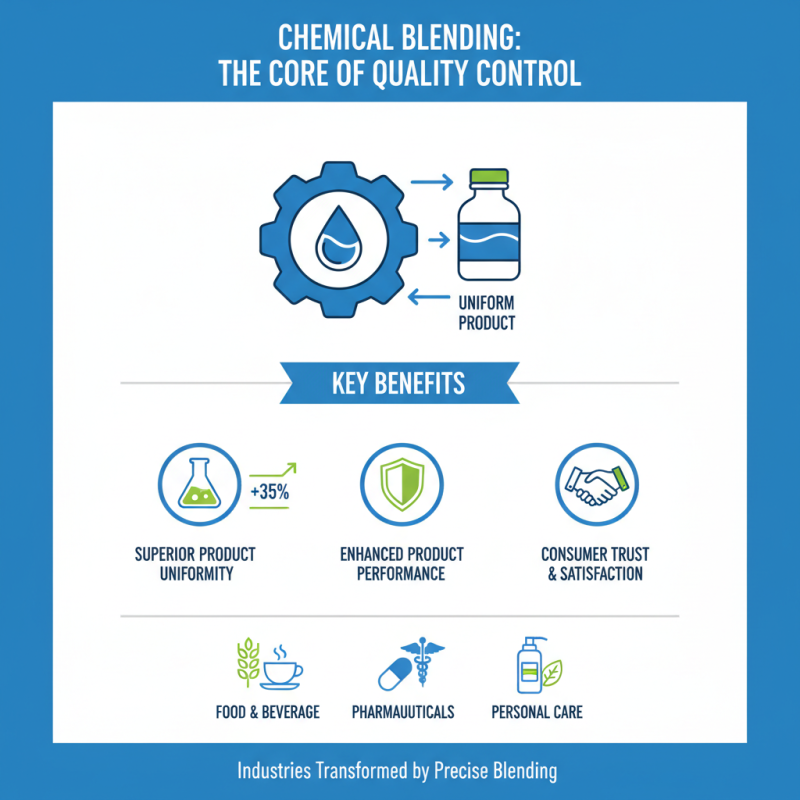

Quality Control Benefits Gained from Effective Chemical Blending

Effective chemical blending plays a crucial role in quality control across various industries. By marrying different chemical components, businesses can achieve superior product uniformity, which is essential for maintaining high standards. Research indicates that a well-executed chemical blending process can enhance product performance by up to 35%, allowing manufacturers to offer products that consistently meet or exceed consumer expectations. This is particularly relevant in sectors such as food and beverage, pharmaceuticals, and personal care, where quality flucuations can lead to significant customer dissatisfaction and financial losses.

Moreover, chemical blending aids in the identification and elimination of impurities, thus ensuring greater safety and efficacy of the final product. Utilizing advanced blending technologies, companies are able to meet regulatory standards more easily, reducing the likelihood of costly recalls due to quality issues. Industry reports suggest that organizations employing rigorous blending protocols can experience a decrease in production waste by approximately 20%. This not only contributes to environmental sustainability efforts but also enhances overall operational efficiency, making chemical blending a pivotal factor in modern industrial practices.

Related Posts

-

How to Effectively Manage Chemical Waste Disposal for Your Business

-

10 Best Practices for Solvent Waste Disposal You Should Know

-

2025 Top 5 Specialty Chemicals for Sustainable Industry Innovations

-

Top 10 Specialty Chemicals That Transform Industries and Boost Innovation

-

Top 10 Superior Chemical Solutions for Industry Efficiency and Performance

-

Top 10 Essential Tips for Safe and Effective Chemical Disposal Strategies