Why Choosing the Right Chemical Vendors is Crucial for Your Business Success

In the complex landscape of the chemical industry, selecting the right chemical vendors is pivotal to ensuring both operational efficiency and competitive edge. A report by the Chemical Market Associates, Inc. reveals that approximately 70% of chemical-related disruptions stem from vendor-related issues, underscoring the importance of strategic vendor management. According to Dr. Emily Carter, a leading expert in supply chain management within the chemical sector, "The success of any chemical operation hinges on the reliability and quality of its suppliers." This statement reflects the foundational role vendors play in the overall supply chain, impacting everything from production timelines to product quality.

Furthermore, a recent analysis by IQVIA indicates that companies engaged in chemical manufacturing that prioritize robust vendor relationships experience a 25% increase in operational performance compared to those that do not. With volatility in the market, fluctuating raw material prices, and increasing environmental regulations, the stakes have never been higher for businesses to align themselves with the right chemical vendors. Proper vendor selection not only mitigates risks but also enhances innovation and sustainability efforts, essential components for thriving in today’s market. As the industry continues to evolve, recognizing the value of capable and trustworthy chemical vendors will be crucial for long-term success.

Importance of Chemical Vendors in Supply Chain Management

In today's competitive market, the role of chemical vendors in supply chain management cannot be overstated. These vendors serve as vital links between businesses and their suppliers, ensuring that the necessary chemicals and raw materials reach manufacturers in a timely and efficient manner. By establishing strong partnerships with reliable chemical vendors, companies can enhance their production processes, minimize downtime, and ultimately improve their overall operational efficiency. A dependable vendor not only provides quality materials but also offers logistical support, expert advice, and consistent availability, strengthening the entire supply chain framework.

Moreover, choosing the right chemical vendors significantly affects a company's ability to respond to market demands and changes. Vendors who are agile and well-integrated within the supply chain can facilitate quicker adjustments, allowing businesses to meet customer needs without compromising on quality or delivery schedules. Effective communication with vendors also fosters collaboration, enabling businesses to innovate and develop new products more swiftly. Therefore, understanding the strategic importance of chemical vendors is crucial for businesses that seek sustainable growth and success in an increasingly dynamic marketplace.

Importance of Chemical Vendors in Supply Chain Management

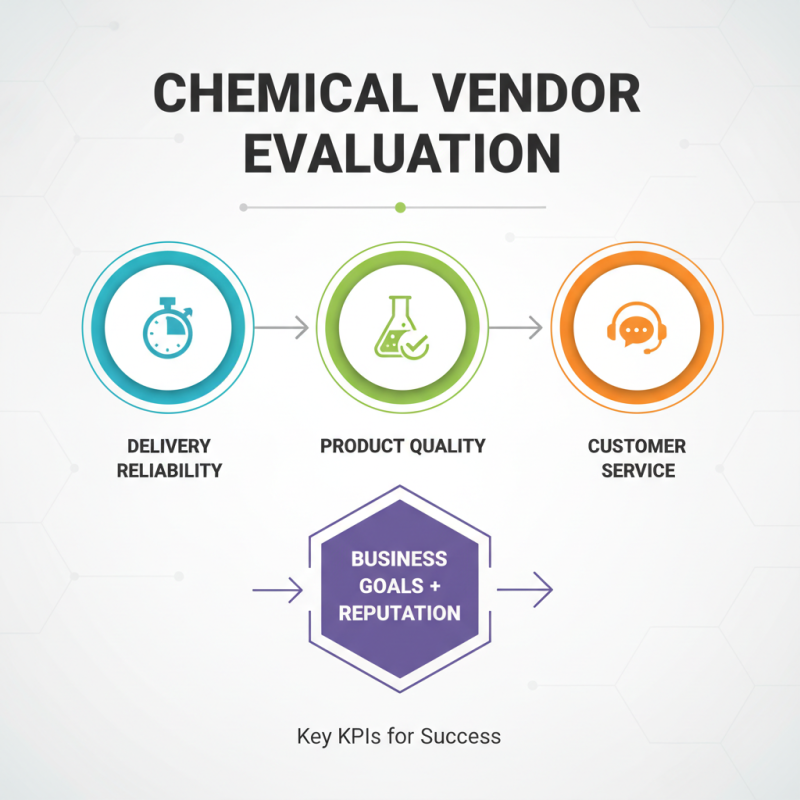

Evaluating Vendor Performance: Key Metrics and Benchmarks

When evaluating chemical vendors, it is essential to establish clear metrics and benchmarks that align with your business goals. Key performance indicators (KPIs) such as delivery reliability, product quality, and customer service responsiveness are crucial. A vendor that consistently meets delivery deadlines not only ensures smooth operations but also helps maintain production schedules. Similarly, assessing the quality of the chemicals supplied is vital, as subpar products can lead to defective end products, negatively impacting your brand reputation.

Additionally, monitoring the vendor's communication and support levels can provide insights into their reliability. Metrics like response time to inquiries, problem resolution efficiency, and technical support availability can significantly influence your collaboration with the vendor. Establishing regular performance reviews and feedback loops can help identify any areas needing improvement, fostering a more productive partnership. Developing these benchmarks allows businesses to make informed decisions when selecting and retaining chemical vendors, ultimately contributing to overall success and operational efficiency.

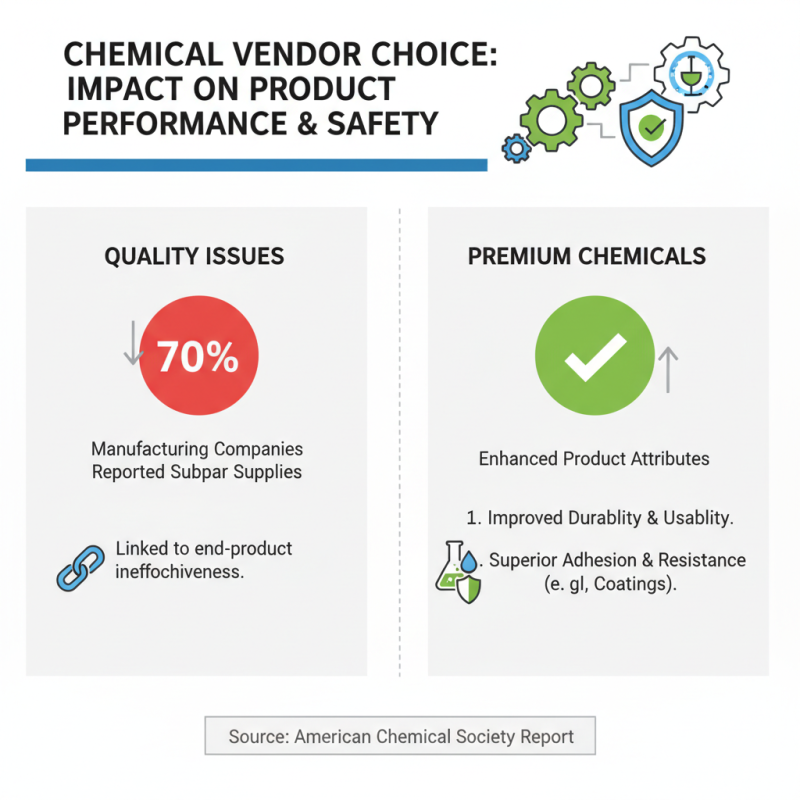

Impact of Quality Chemicals on Product Performance and Safety

The choice of chemical vendors directly influences product performance and safety across various industries. According to a report from the American Chemical Society, 70% of companies in manufacturing sectors reported quality issues linked to subpar chemical supplies, impacting their end products’ effectiveness. High-quality chemicals ensure that products meet specified performance criteria, enhancing durability and usability. For instance, in the coatings industry, the use of premium-grade resins significantly improves adhesion and resistance to environmental factors, which is critical for long-lasting applications.

Moreover, safety is paramount in chemical handling and usage. A study published in the Journal of Hazardous Materials indicates that over 60% of industrial accidents are associated with low-grade or improperly formulated chemicals. Choosing reliable vendors who prioritize quality control can mitigate risks associated with hazardous substances, thus ensuring compliance with safety regulations and protecting both employees and consumers. Industry leaders who invest in top-tier chemical suppliers not only enhance product safety but also reinforce their market reputation, ultimately leading to increased customer trust and continued business success.

Cost Analysis: Balancing Price and Quality in Chemical Procurement

In the landscape of chemical procurement, the balance between price and quality can significantly influence a business's overall operational success. While it might be tempting to prioritize cost savings by opting for lower-priced chemicals, this approach can lead to long-term repercussions. Low-quality materials can result in subpar product performance, operational inefficiencies, and even regulatory compliance issues, ultimately jeopardizing a business’s reputation and financial health. Therefore, businesses must conduct a thorough cost analysis that evaluates not just the purchase price but also the implications of quality on performance and reliability.

Incorporating a comprehensive evaluation process in procurement can help companies make informed decisions. This involves assessing the total cost of ownership, which includes the initial purchase price, storage, handling, potential waste management, and the impact on production processes. By considering these factors, businesses can identify vendors that provide high-quality chemicals at a competitive price, ensuring that they do not sacrifice quality for cost.

Establishing strong relationships with reliable vendors can also lead to negotiations for better pricing without compromising on quality, reinforcing the idea that cost efficiency in procurement should go hand in hand with a commitment to excellence. This strategic approach not only contributes to immediate savings but enhances the long-term sustainability and success of the business.

Regulatory Compliance and Risk Management in Chemical Sourcing

When it comes to chemical sourcing, regulatory compliance is paramount for businesses aiming for long-term success. Navigating the complex landscape of chemical regulations requires a thorough understanding of local and international laws. Failing to comply can lead to severe repercussions, including hefty fines, legal action, and damage to a company's reputation. Therefore, selecting chemical vendors who exhibit a strong commitment to compliance ensures that all products meet the necessary safety and environmental standards, mitigating risks associated with noncompliance.

In addition to compliance, risk management plays a vital role in the sourcing process. A reliable chemical vendor should have robust risk management strategies in place to assess and address potential hazards associated with their products. This involves conducting thorough risk assessments, maintaining transparent communication about product safety data sheets, and implementing quality control measures. By partnering with vendors who prioritize safety and risk management, businesses not only protect their assets but also foster a culture of responsibility that resonates throughout their operations and supply chains.

Related Posts

-

Top 10 Specialty Chemicals That Transform Industries and Boost Innovation

-

2025 Top 5 Specialty Chemicals for Sustainable Industry Innovations

-

10 Best Practices for Solvent Waste Disposal You Should Know

-

What is the Role of Industrial Chemicals in Modern Manufacturing Processes

-

2025 Top 10 Specialty Chemicals Innovations Transforming Industries

-

Top 10 Essential Tips for Safe and Effective Chemical Disposal Strategies