Essential Tips for Effective Chemical Blending Techniques?

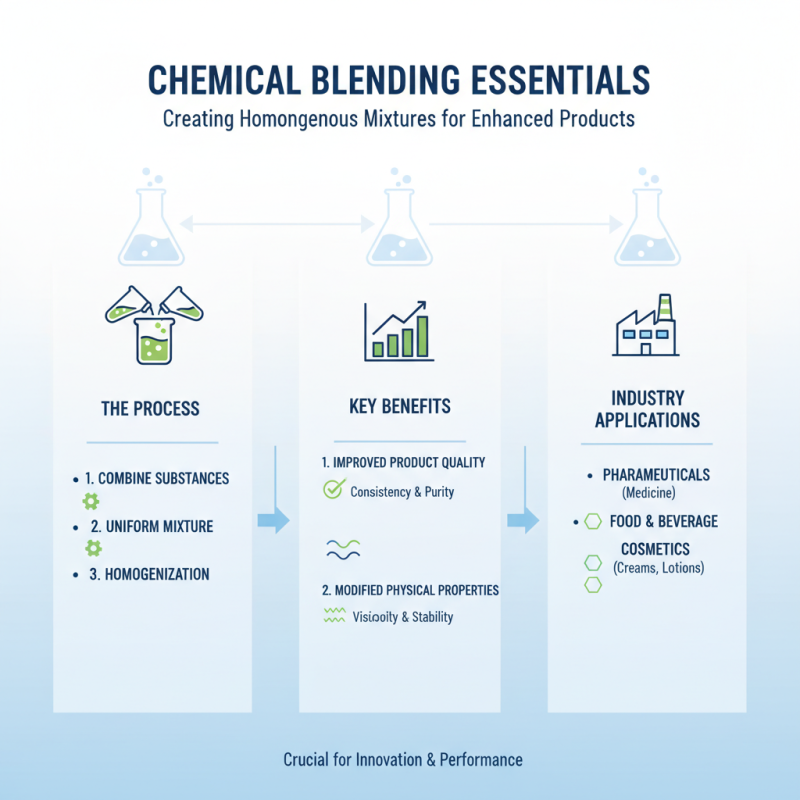

Chemical blending is a critical process in various industries, including pharmaceuticals, food and beverage, and cosmetics. According to a report by MarketsandMarkets, the global chemical blending market is projected to reach $20 billion by 2025. This growth underscores the importance of mastering effective blending techniques to enhance product quality and consistency.

Achieving an optimal blend requires not only the right equipment but also an understanding of material properties. Factors like viscosity and particle size can significantly affect the blending outcome. A study from the American Institute of Chemical Engineers highlights that improper blending can lead to inconsistencies, waste, and reduced product efficacy. These challenges emphasize the need for ongoing refinement in blending practices and technologies.

Despite advancements, many manufacturers struggle with achieving uniformity. Techniques often vary, resulting in uneven products that fail to meet customer expectations. Emphasizing training and technology can help address these shortcomings while promoting safer and more efficient operations. By focusing on effective chemical blending, companies can secure their place in a competitive market.

Understanding the Basics of Chemical Blending

Chemical blending is a crucial process in various industries. Understanding the basics is essential. This entails combining different substances to create a homogeneous mixture. Proper blending can enhance product quality. It also affects physical properties, like viscosity and stability.

Getting the right proportions is key. Small changes in ratios can lead to significant differences. Experimenting with different blends helps identify optimal combinations. Always record your methods. This way, you can replicate successful results or adjust those that didn't meet expectations.

Tip: Take the time to mix slowly. Rapid mixing can create air bubbles. This may compromise the product quality. Another tip: Use appropriate equipment. A blender that does not meet specifications can lead to inconsistent results. Remember, it's okay to makes mistakes. Learn from them to improve your techniques.

Importance of Material Compatibility in Blending

When it comes to chemical blending, material compatibility is crucial. Not all substances work well together. Some can create adverse reactions that compromise the blend’s quality. Understanding the properties of each component is essential. For instance, mixing polar and non-polar solvents often leads to separation. This mistake can waste time and resources.

Another common issue arises with temperature sensitivity. Certain chemicals react differently at various temperatures. Mixing at the wrong temperature can cause degradation or unwanted byproducts. This emphasizes the need for careful monitoring. Engaging in trial blends may reveal hidden incompatibilities. Many teams overlook this step, leading to costly failures.

Moreover, pay attention to the physical characteristics of the materials. Viscosity, solubility, and particle size all play a role in achieving a consistent blend. If components do not match well, the final product may be inconsistent. It’s worth conducting thorough compatibility tests before scaling up production. Reflection on past blending processes can provide insights for improvement. Taking these factors into account helps ensure successful blending efforts.

Essential Tips for Effective Chemical Blending Techniques

| Material Type | Compatibility Score (1-10) | Recommended Blending Method | Common Applications |

|---|---|---|---|

| Polyethylene | 8 | High-Shear Mixing | Packaging Materials |

| PVC | 7 | Batch Mixing | Construction Materials |

| Polypropylene | 9 | Continuous Mixing | Automotive Parts |

| Nylon | 6 | Tumble Blending | Textile Industry |

| Polyester | 8 | Extrusion Mixing | Bottles and Fibers |

Techniques for Achieving Consistent Blend Quality

Achieving consistent blend quality in chemical blending is crucial. Inaccuracies can lead to product variances that impact performance. According to a report by the American Chemical Society, nearly 30% of blending operations fail to meet specifications due to inadequate methods. This highlights the need for improved techniques.

Proper calibration of equipment is vital. Instruments should be routinely checked, ensuring they operate within set parameters. A study from the International Journal of Chemical Engineering reveals that only 60% of blending operations maintain proper equipment maintenance. This negligence can result in significant quality discrepancies. Adjusting mixing speed and time also plays a critical role. Over-mixing or under-mixing can create uneven distributions of components.

Monitoring environmental factors is another essential aspect. Temperature fluctuations can affect reagent behavior, leading to inconsistent blends. In fact, a survey showed that 45% of blending facilities do not account for temperature variations. Companies often overlook this point, prompting a deeper reflection on the importance of comprehensive monitoring. By paying attention to these factors, blending processes can be significantly optimized, yet many still struggle with implementation.

Essential Tips for Effective Chemical Blending Techniques

This bar chart illustrates the factors affecting blend consistency in chemical blending techniques. The categories include Temperature, Mixing Speed, Duration, and Ingredient Quality, with respective blend consistency scores out of 100.

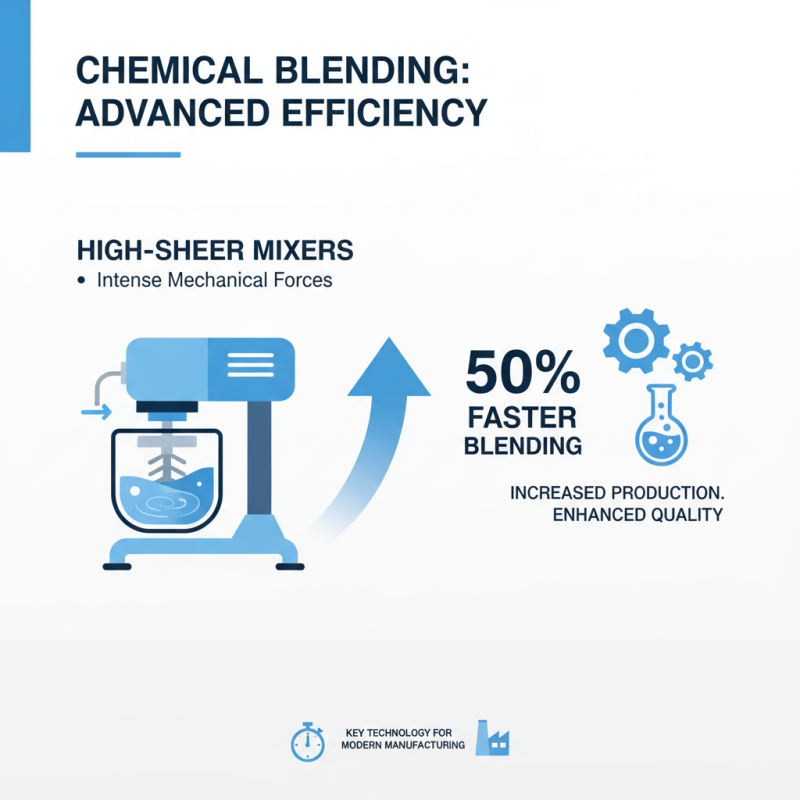

Equipment and Technology for Efficient Chemical Mixing

Effective chemical blending relies heavily on advanced equipment and technology. For instance, high-shear mixers are widely used in the industry. These mixers generate intense mechanical forces, which can significantly improve blending efficiency. A study indicated that high-shear mixing can reduce blending times by up to 50%. This efficiency is crucial for companies aiming to increase production without compromising quality.

Another vital piece of equipment is the ribbon blender. It is recognized for its ability to blend dry solids uniformly. Reports show that ribbon blenders can achieve a mixing uniformity coefficient as low as 5%, which is impressive. However, these machines are not without their challenges. Their maintenance can be intensive, and an unclean machine can lead to cross-contamination. Regular inspections are necessary to ensure optimal performance and safety.

Emerging technologies, such as real-time monitoring systems, are also shaping the field. These systems can provide immediate feedback on the blending process, helping operators make instant adjustments. A lack of such technology can lead to quality inconsistencies. Implementing these tools may require upfront investment but can pay off significantly in the long run. Balancing cost and technology is crucial for companies looking to excel in chemical blending.

Safety Precautions in Chemical Blending Processes

Safety is paramount in chemical blending processes. Studies indicate that improper handling of chemicals leads to significant accidents. In fact, the American Chemical Society found that nearly 25% of chemical-related incidents stem from lack of safety training. This percentage reveals the need for proper precautions and education in handling materials.

A crucial aspect of safety is personal protective equipment (PPE). Wearing gloves, goggles, and respirators can prevent exposure to harmful substances. According to the Occupational Safety and Health Administration (OSHA), failure to use appropriate PPE can increase health risks by up to 45%. Workers often underestimate these risks, leading to dangerous situations.

Ventilation is another factor that requires attention. Inadequate airflow can lead to toxic fume accumulation. A study by the National Institute for Occupational Safety and Health (NIOSH) suggested that proper ventilation reduces harmful exposure by over 60%. Yet, many facilities overlook this critical aspect. Reflecting on these details can save lives and improve the overall safety culture in the workplace.

Related Posts

-

Top 10 Essential Features Every Chemical Lab Should Have

-

What is the Role of Industrial Chemicals in Modern Manufacturing?

-

Top 10 Essential Features of Chemical Labs for Effective Research

-

Top 7 Carolina Chemicals for Enhanced Industrial Efficiency

-

2025 Top 5 Specialty Chemicals for Sustainable Industry Innovations

-

Top 10 Superior Chemical Solutions for Industry Efficiency and Performance