How to Find Superior Chemical Solutions for Your Business Needs

In today's competitive landscape, businesses across various industries increasingly rely on chemical solutions to enhance their operations and drive innovation. Identifying superior chemical solutions tailored to specific business needs can significantly impact productivity, safety, and overall performance. Companies must navigate a complex array of options, ensuring that they make informed decisions that align with their operational goals and regulatory requirements.

To uncover superior chemical solutions, organizations should adopt a strategic approach that involves thorough research, consultation with experts, and evaluation of potential suppliers. Understanding the unique challenges faced by a business is crucial in selecting the right chemical products that not only meet industry standards but also provide the necessary efficacy and cost-effectiveness. Furthermore, fostering strong partnerships with suppliers can lead to better insights and access to cutting-edge innovations in the chemical sector, enhancing the competitiveness of the business in the long run.

Evaluating factors such as environmental impact, compliance with safety regulations, and the specific applications of chemical solutions will empower businesses to make educated choices. By prioritizing the search for superior chemical solutions, organizations can optimize their processes, innovate their product offerings, and ultimately achieve sustainable growth.

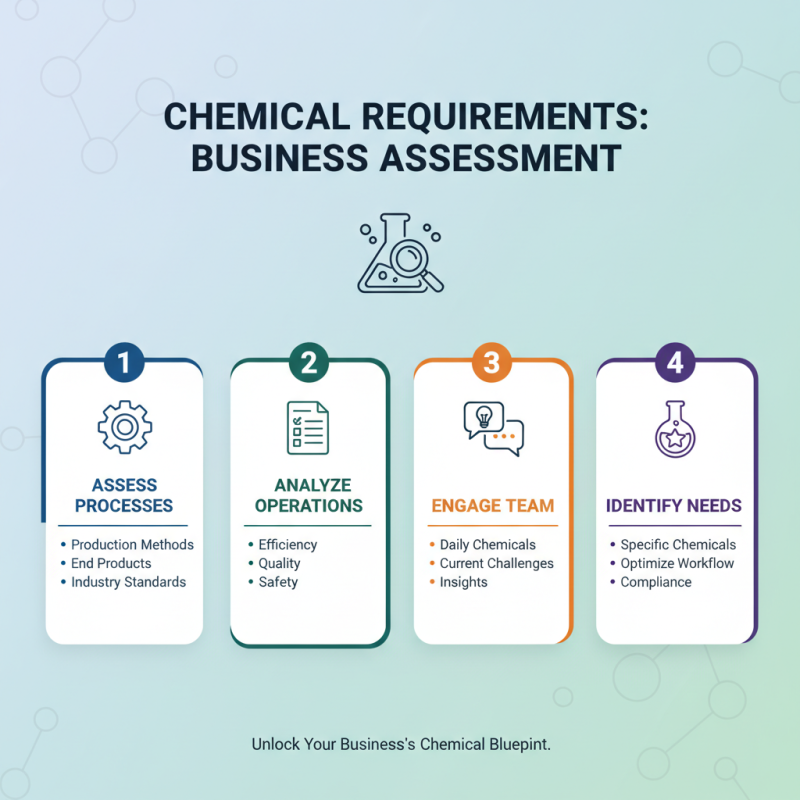

Identifying Your Business's Unique Chemical Requirements

Identifying your business's unique chemical requirements begins with a thorough assessment of your processes and end products. Each business operates differently, leading to distinct chemical needs influenced by production methods, industry standards, and safety regulations. Conducting a detailed analysis of your operations can help uncover the specific chemicals that contribute to efficiency, quality, and safety in your work environment. Engage with your team to gather insights on which chemicals are integral to daily operations and where challenges currently exist.

Moreover, it’s crucial to stay informed about the latest advancements in chemical technologies and their applications. This knowledge allows businesses to evaluate alternatives that might improve performance or reduce costs. Networking with industry experts or participating in relevant workshops can provide valuable insights into innovative chemical solutions tailored to your sector. By actively exploring various chemical options and analyzing their suitability, businesses can make informed choices that align with their unique operational needs, ultimately leading to enhanced performance and productivity.

Exploring Different Types of Chemical Solutions Available

When exploring different types of chemical solutions available for business needs, it's crucial to first identify the specific requirements and applications for which these chemicals will be utilized. Common categories of chemical solutions include solvents, adhesives, coatings, and cleaning agents, each offering unique properties suited for various industrial applications. For instance, solvents are instrumental in processes such as paint thinning and chemical extraction, where their ability to dissolve other substances is essential. Meanwhile, adhesives play a vital role in manufacturing and construction, providing strong bonding for diverse materials.

In addition to these standard categories, specialty chemical solutions have emerged to address particular challenges in industries like agriculture, pharmaceuticals, and food production. Biodegradable solutions are gaining traction as businesses seek environmentally friendly options that do not compromise performance. Meanwhile, performance-enhancing chemicals tailored for specific processes, such as surfactants in cleaning or catalysts in chemical reactions, help improve efficiency and effectiveness. Understanding the array of available chemical solutions and their specific applications empowers businesses to make informed decisions that align with both operational requirements and sustainability goals.

How to Find Superior Chemical Solutions for Your Business Needs

| Chemical Solution Type | Applications | Industry Sector | Benefits |

|---|---|---|---|

| Solvents | Cleaning and Degreasing | Manufacturing | Effective cleaning, fast evaporation |

| Acids | pH Adjustment, Metal Treatment | Metal Processing | High reactivity, versatile applications |

| Bases | Cleaning Agents, Chemical Manufacturing | Cleaning, Chemical Production | Strong cleaning power, cost-effective |

| Surfactants | Emulsification, Wetting Agents | Cosmetics, Cleaning Products | Improves product effectiveness, enhances texture |

| Polymers | Coatings, Adhesives | Construction, Manufacturing | Durability, versatility in application |

Evaluating Supplier Capabilities and Reliability

When evaluating supplier capabilities and reliability in the chemical industry, businesses must consider several key factors to make informed decisions. A recent report by the International Chemical Industry Association highlights that over 60% of companies identify supplier reliability as a critical factor influencing their procurement strategies. This reliability is measured through parameters such as on-time delivery, quality consistency, and responsiveness to issues, which collectively impact a firm's operational efficiency and cost management.

In addition to reliability, the capability of suppliers to meet specific business needs is paramount. This includes evaluating their production capacity, technological advancements, and compliance with industry standards. According to a study by the Chemical Industry Health and Safety Institute, suppliers that invest in modern technology and maintain high safety standards not only improve product quality but also reduce the risk of disruptions, making them more appealing to potential partners.

It’s essential to assess certifications such as ISO and REACH compliance, as they play a significant role in ensuring that suppliers can adhere to both safety regulations and quality benchmarks necessary for your operations.

By focusing on these aspects, businesses can secure partnerships with suppliers that not only fulfill current demands but also adapt to future needs, ensuring long-term sustainable growth in a competitive marketplace.

Conducting Cost-Benefit Analysis for Chemical Solutions

Conducting a cost-benefit analysis is essential for businesses seeking to adopt new chemical solutions. This method allows companies to weigh the financial implications against the potential benefits that these solutions may bring. To begin, organizations should identify all relevant costs, including initial investment, operational expenses, and any necessary training for staff. It is crucial to consider both direct costs, such as purchasing the chemicals, and indirect costs that may arise from their usage, like environmental compliance or disposal fees.

Once costs are fully outlined, the next step involves evaluating the benefits that the chemical solutions offer. These benefits can range from improving product quality to enhancing operational efficiency and decreasing long-term expenditure. By quantifying these advantages, businesses can better understand the return on investment (ROI) of implementing new chemical processes. A thorough analysis will help decision-makers determine not only the financial feasibility of the solutions but also their alignment with the overall goals of the company, ensuring that the chosen path leads to sustainable growth and competitive advantage in the marketplace.

Cost-Benefit Analysis of Chemical Solutions

This chart compares the estimated costs and benefits of various chemical solutions based on a hypothetical business scenario. The values are represented in thousands of dollars.

Ensuring Compliance with Safety and Regulatory Standards

In the ever-evolving landscape of chemical solutions, ensuring compliance with safety and regulatory standards is paramount. Businesses must not only prioritize the efficacy of their chemical products but also their adherence to regulations that safeguard health and the environment. This compliance helps mitigate risks associated with hazardous materials and enhances the overall credibility of the business.

Tips for maintaining compliance include regularly reviewing local and international regulations applicable to your industry. Stay updated on changes in chemical safety laws and standards by subscribing to relevant industry newsletters and participating in webinars. Additionally, conduct thorough audits of your chemical inventory to ensure that all products meet the required safety measures and that proper documentation is available and easily accessible.

Another vital aspect is to partner with suppliers who prioritize compliance and safety in their practices. Engaging with these suppliers can provide you with insights into best practices and emerging regulations, aiding in the development of safer chemical solutions. By fostering strong relationships within the supply chain, businesses can better navigate the complexities of regulatory frameworks while ensuring that their products are both effective and safe for use.

Related Posts

-

Top 10 Superior Chemical Solutions for Industry Efficiency and Performance

-

2025 Top 5 Specialty Chemicals for Sustainable Industry Innovations

-

Top 10 Benefits of Hiring a Chemical Consultant for Your Business

-

What Is Chemistry Chemicals Exploring Common Types and Their Applications

-

10 Best Practices for Solvent Waste Disposal You Should Know

-

How to Effectively Manage Chemical Waste Disposal for Your Business