2026 How to Choose the Right Chemical Supply for Your Business Needs?

Choosing the right chemical supply for your business can be challenging. Industry expert Dr. Sarah Thompson emphasizes, "Quality chemicals are essential for operational success." Selecting a supplier impacts your production, safety, and costs.

When evaluating potential chemical suppliers, consider the range of products they offer. Make sure they supply all the chemicals your business needs. Check their certifications and compliance with industry regulations. Reliable suppliers ensure safety and quality in their products.

Also, consider the supplier’s customer service. Are they responsive? Do they provide technical support? These factors can influence your business operations. Remember, finding the right chemical supply is not just about price; it involves building a trustworthy relationship. Make a thoughtful choice for your business’s future.

Understanding Your Business's Chemical Supply Requirements

Understanding the specific chemical supply requirements for your business is crucial. A thorough evaluation of your operations helps to identify the types and quantities of chemicals you need. Consider your production processes, safety standards, and storage capabilities. This ensures you don't end up with excess or inadequate supply.

**Tips:** Start by assessing your current usage. Analyze past orders and identify trends. This will give you an idea of what you regularly require. Next, involve your team in discussions. Their insights can reveal needs you might overlook.

When selecting a supplier, think about their reputation and reliability. Look for reviews and feedback, but remember that no supplier is perfect. Trust is built over time, and initial hiccups are common. Balance your expectations and be prepared to adapt to new arrangements.

**Tips:** Request samples before committing. Testing quality can save you from costly decisions later. Staying flexible in your supply choices can lead to better long-term relationships with suppliers.

Evaluating Chemical Suppliers: Key Factors to Consider

When evaluating chemical suppliers, several key factors come into play. The quality of chemicals is paramount. Suppliers must provide detailed specifications and certifications. A lack of transparency in quality can lead to serious issues. It's important for businesses to ask for samples and test them thoroughly.

Reliability is another critical aspect. Suppliers should have a solid track record of meeting deadlines. Late deliveries can disrupt production schedules. Understand their logistics processes. Are they equipped to handle urgent demands? This question can reveal much about their reliability.

Cost is always a consideration, but it shouldn't be the sole factor. Sometimes, a lower price reflects inferior quality. Matching supply capabilities with business needs is vital. Evaluate how they manage inventory and sourcing. Transparency about potential shortages is essential. Seek suppliers who proactively communicate. Such partnerships build trust over time.

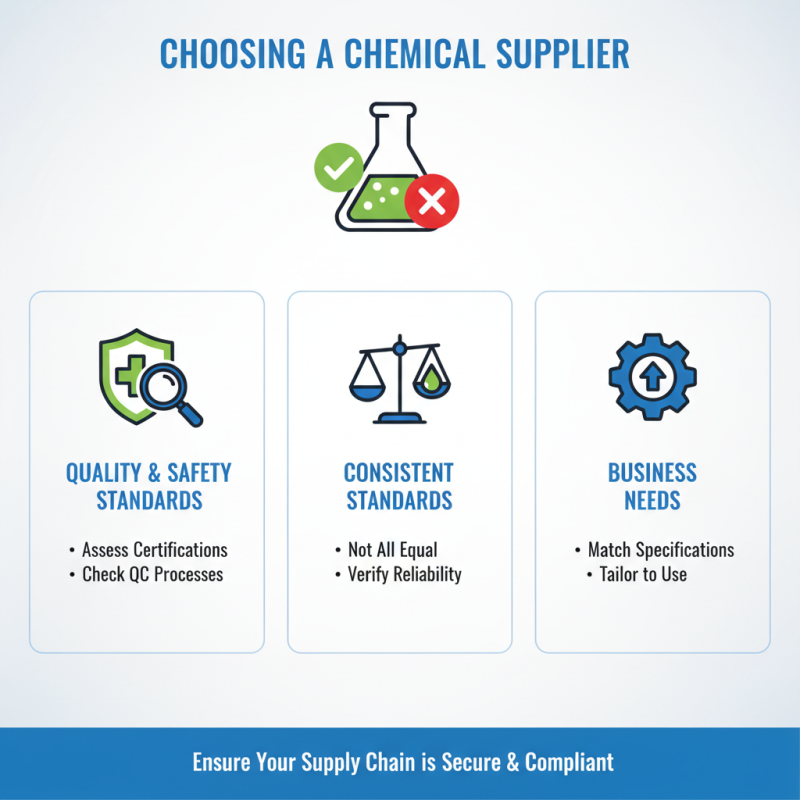

Evaluating Key Factors for Choosing Chemical Suppliers

Assessing Quality and Safety Standards in Chemical Supply

When choosing a chemical supply, assessing quality and safety standards is crucial. Not all suppliers maintain the same standards. Quality control processes vary greatly. You need to ensure that the chemicals meet your specific business needs.

Consider checking certifications. Look for suppliers with recognized quality assurances. ISO certifications can indicate that the company adheres to international standards. Additionally, review safety data sheets (SDS). These documents provide essential information about handling and hazards. A reliable supplier will be transparent about their safety practices.

**Tip**: Ask for samples before making large orders. This way, you can test the chemical in your processes. Verify its quality and safety claims before committing.

Evaluate their track record. Seek suppliers who have experience in your industry. A history of compliance with regulations is vital. Don’t hesitate to ask for references. Sometimes, you might find inconsistencies between the promises and reality. A supplier's communication style can reveal their reliability. If they are difficult to reach, that could be a red flag.

**Tip**: Engage with their technical support team. Good communication is a good sign of a trustworthy supplier.

Comparing Pricing and Delivery Options among Suppliers

Choosing the right chemical supplier is crucial for your business. Pricing and delivery options significantly affect your operational efficiency. Data from recent industry reports show that up to 30% of companies face challenges with delayed deliveries. This can disrupt production schedules and impact customer satisfaction.

When evaluating suppliers, consider their pricing structure carefully. A low upfront cost may hide additional fees. A comprehensive report by Chemical Market Analytics emphasizes that hidden costs can inflate total expenses by up to 15%. This needs careful calculation. Clear pricing with no surprises is ideal for maintaining your budget.

Delivery options are equally critical. A supplier with flexible shipping can adapt to your needs better. Some suppliers offer expedited shipping services. However, these often come at a premium. According to the Supply Chain Management Review, 45% of businesses prefer suppliers who provide predictable delivery schedules over those who solely focus on cost. This is a telling statistic that underscores the importance of reliability in supply chains.

Building Long-term Relationships with Chemical Suppliers

Building long-term relationships with chemical suppliers can be a game-changer for your business. When you find the right supplier, it often leads to improved communication and trust. You receive better support and tailored solutions for your specific needs. If your supplier understands your requirements, they can anticipate challenges before they arise. This proactive approach helps avoid disruptions in the supply chain.

However, choosing the right supplier is not always straightforward. Initial costs might be attractive, but long-term reliability is vital. Sometimes, it's tempting to go for cheaper options. This can lead to inferior quality that affects your products. Reflecting on past experiences with suppliers can provide valuable insights. Assess how those partnerships impacted your efficiency and product quality.

It's essential to engage suppliers regularly. Frequent discussions about your goals and challenges can foster understanding. Over time, this open dialogue nurtures collaboration and innovation. However, it is crucial to remain aware of shifting needs in your business. Suppliers must adapt to these changes too. A mutually beneficial relationship evolves with both parties growing together.

Related Posts

-

How to Find the Right Chemical Consultant for Your Business?

-

Top 10 Benefits of Hiring a Chemical Consultant for Your Business

-

How to Source Chemical Raw Materials Efficiently for Your Business Needs

-

Why Are Chemical Plant Jobs in High Demand and How to Get One

-

Top 10 Superior Chemical Solutions for Effective Industrial Applications

-

Why Choosing the Right Chemical Vendors is Crucial for Your Business Success